The SiOx CO2 method

Our machines are very versatile. The machine has a ”platform” consisting of a treatment reactor, a storage and a recovery system for CO2 and additives. With small modifications, the machines are employed in very diverse industries such as leather processing, metal treatment , modification of plastics and biopolymers and many special tasks e.g. in the pharma industry etc. The ”platform design” enables us to reduce construction costs – whilst keeping all the benefits of our advanced technology.

The three basic processes which can be carried out with our hardware:

- Cleaning

- Extraction

- Impregnation of water-soluble or non-water soluble materials

The key advantages using SiOx CO2 processes are

- LCO2 is non-toxic and non flammable

- LCO2 is recovered from gaseous waste streams from chemical industries and is therefore a sustainable resource. No extra contribution to global warming, in other words.

- SiOx’s LCO2 process does not require a drying which contributes to the low energy needs. SiOx’s LCO2 process does not emit volatile organic solvents and it does not pollute ground water.

- Low temperature process

- Similar to organic solvents, dissolves fats

- Can replace PER and hydrocarbon solvents

- Recycled within the machine to 98.5 %

- Low energy consumption

- Low surface tension – penetrates all porous materials

- Highly cost-efficient

- Savings of process water and energy

- Fast and efficient process

- No odour, antibacterial

- Easy recovery of process chemicals

What is liquid CO2 (LCO2)?

At Atmospheric pressure CO2 is an odurless gas. If you increase the pressure the gas will turn into a clear liquid. By increasing the pressure and temperature to a point above 73 Bars and 31 degrees Celsius, CO2 turns into its supercritical state. At the liquid state, CO2 has a solvent strength in the range of acetone and hexane . The viscosity and surface tension is orders of magnitudes lower than water and organic solvents.

By altering the temperature and pressure or by including an additive, the solvent power of CO2 can be optimized for a specific application.

Using SiOx machines technology, it is possible to replace processes traditionally carried out in benzene, perchloroethylene, hydrocarbons and other toxic and/or flammable solvents by environmentally friendly, non-toxic carbon dioxide under pressure.

CO2 under pressure has excellent cleaning properties. It is safe to work with and reaches the smallest structures due to very low surface tension. Goods can be placed in the machine in dry state, and after the treatment they are still dry.

Supercritical CO2 is most well known in the field. We offer liquid CO2 (LCO2) technology which has all the advantages of supercritical CO2 – but at significantly lower investment costs.

A process cycle explained

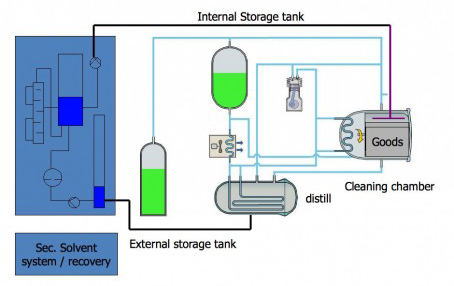

1) Goods are placed in a treatment chamber. The air inside the chamber is evacuated after the door has been securely closed.

2) CO2 is the introduced into the cleaning chamber from the internal storage tank.

3) Depending on type of process, the additives are pumped in under pressure and mixed with the liquid CO2 in the treatment chamber. The goods can either be rotated in the treatment chamber or held still by pumping the CO2 past the goods. The operating temperature is generally around 8 to 25 degrees Celsius. Due to the high gas phase density, the objects will flow very gently if rotated compared to other methods. Mechanical abrasion is avoided.

4) Liquid CO2 is then transferred to a recovery unit, which separates the CO2 from any additives or dissolved grease . The CO2 is evaporated and condensed and transferred back clean to the internal storage tank. Thanks to the patented recovery process, CO2 can be distilled very efficiently with a very low energy consumption. In some applications the additives will be recovered as well.

5) Depending on the application, step 4) is repeated with our without additives

6) The pressure in the treatment chamber is lowered down to atmospheric pressure and transferred back to the storage tank via the recovery unit. In total, approximately 98.5% of the CO2 used is recovered.

7) At atmospheric pressure the door can be opened and the goods be taken out. Goods will come out completely dry and without any odor. No drying process is necessary and the goods are at no stage during the process subject to higher temperatures than 30 degrees Celsius.